✈️ AAVAD INSTRUMENT PVT. LTD.: Precision, Safety & Reliability for the Aerospace Industry

⚙️ Introduction

The aerospace industry demands absolute precision. Aircraft, satellites, and propulsion systems must operate under extreme temperatures, vibration, pressure, and environmental changes. Therefore, every sensor must deliver accurate, repeatable, and reliable measurements.

AAVAD INSTRUMENT PVT. LTD., a trusted Indian manufacturer of high-precision thermocouples, RTDs, flow meters, and transmitters, provides instrumentation designed for aerospace-grade performance. Moreover, these devices comply with global standards, ensuring traceability, safety, and long-term reliability. As a result, aerospace companies achieve exceptional control over manufacturing and testing processes.

🚀 1️⃣ Role of Instrumentation in Aerospace Engineering

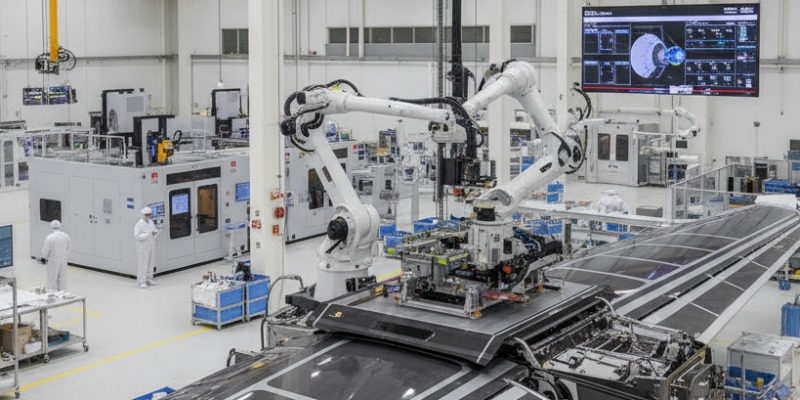

Instrumentation forms the backbone of aerospace production and testing. Additionally, each step—whether temperature control, fuel flow monitoring, or hydraulic system testing—requires precise data to maintain safety and quality. Furthermore, modern aerospace systems rely heavily on automation, making high-accuracy sensors essential.

🔹 Used In:

Jet engine and turbine testing

Fuel and hydraulic systems

Environmental and altitude test chambers

Composite curing and autoclave systems

Aerospace component machining and inspection

🎯 Objective:

Ensure accuracy, repeatability, and full traceability in accordance with AS9100, ISO 9001, and FAA/EASA requirements.

🌡️ 2️⃣ Temperature Measurement in Aerospace Manufacturing & Testing

Temperature control is essential in aerospace operations. For example, superalloy heat treatment, engine testing, and composite curing all depend on stable and accurate temperature monitoring. Therefore, industries require sensors that perform reliably even under extreme heat and vibration.

🔹 AAVAD Temperature Solutions:

Thermocouples (K, N, R, S, B Types): Up to 1800°C

RTD Sensors (PT100/PT1000): ±0.1°C accuracy

Surface & Immersion Probes: For engine and chamber testing

Flameproof & Vibration-Resistant Designs: Ideal for turbine systems

🔹 Applications:

Turbine and jet engine temperature monitoring

Composite curing in autoclaves

Wind tunnel and thermal simulation chambers

Superalloy heat treatment furnaces

⭐ Benefits:

High stability with precise temperature control

Reduced thermal fatigue and material failure

Tested, calibrated, and traceable for aerospace compliance

💡 Example:

In a turbine blade heat-treatment facility, AAVAD’s R-Type thermocouples help maintain accurate furnace temperature curves. Consequently, the final blades achieve consistent mechanical strength and airworthiness approval.

💧 3️⃣ Flow Measurement in Fuel, Hydraulic & Cooling Systems

Aerospace systems rely on controlled flow of fuel, hydraulics, coolants, and lubricants. Moreover, precise flow monitoring ensures safe engine performance and reliable ground testing. Additionally, stable flow rates help prevent pressure drops, equipment damage, and unexpected shutdowns.

🔹 AAVAD Flow Meter Solutions:

Electromagnetic Flow Meters: For coolants and fuel mixtures

Insertion Flow Meters: For large aerospace pipelines

Telemetry Flow Meters: For remote test sites and field facilities

🔹 Applications:

Jet fuel measurement

Engine lubrication lines

Thermal vacuum chamber cooling

Environmental test chambers

Ground support equipment

⭐ Benefits:

±0.5% accuracy with stable repeatability

Withstands pressure fluctuations and high temperature

Integrates easily with SCADA, DAQ, and PLC systems

💡 Example:

During an endurance test, AAVAD’s telemetry-enabled flow meter tracks coolant flow in real time. As a result, engineers receive instant alerts and validation data for flight-readiness checks.

⚙️ 4️⃣ Pressure & Environmental Monitoring

Pressure and environmental monitoring are essential for maintaining safety in aerospace manufacturing and testing. Additionally, stable pressure readings help protect components, hydraulic systems, and cleanroom environments.

🔹 AAVAD Solutions:

Pressure Transmitters & Gauges: For fluid and gas systems

Differential Pressure Sensors: For cleanrooms and airflow tests

Level Sensors: For lubrication and hydraulic tanks

🔹 Applications:

Aircraft fuel and hydraulic lines

Altitude and environmental simulation chambers

Component testing in cleanrooms

Ground support utilities

⭐ Benefits:

Reliable under high pressure and vibration

Low drift and high repeatability

Meets aerospace-grade calibration and compliance standards

AS9100 Aerospace Standard – https://asq.org

FAA Regulations – https://www.faa.gov

EASA Standards – https://www.easa.europa.eu

NASA Technical Reports – https://ntrs.nasa.gov

ISO 9001 Quality Management – https://www.iso.org

🛰️ AAVAD Advantage for Aerospace & Defense

| AAVAD Advantage | Value to Aerospace & Defense |

|---|---|

| 🛰️ High-Temperature Durability | Performs up to 1800°C for engine applications |

| ⚙️ Precision Engineering | Meets aerospace-level accuracy and repeatability |

| 🧾 ISO Certified | Ensures calibration traceability and documentation |

| 💻 Automation Ready | Integrates with SCADA, PLC, DAQ, and IoT systems |

| 🧱 Rugged Industrial Design | Resists vibration, pressure, and extreme heat |

| 🇮🇳 Made in India | Supporting “Atmanirbhar Bharat” and local aerospace growth |

🏁 Conclusion

In aerospace engineering, precision is not optional — it is the foundation of safety. From component manufacturing to high-pressure testing, accurate measurement ensures reliability and mission success.

By using AAVAD’s thermocouples, RTD sensors, flow meters, and transmitters, aerospace companies gain:

✔ Exceptional measurement accuracy

✔ Strong traceability and data integrity

✔ Compliance with global standards

✔ Long-term stability under extreme conditions

AAVAD INSTRUMENT PVT. LTD. – Precision That Powers the Sky.

✔ Thermocouples

Aerospace-Grade Thermocouple Sensors

✔ RTD Sensors

RTD Sensors for Engine & Environmental Testing

✔ Flow Meters

Flow Meters for Cooling & Fuel Monitoring

✔ Pressure Transmitters

Industrial Pressure Transmitters for Aerospace

✔ View All Instruments