⚡AAVAD Instruments: Precision Process Control for Electronics & Semiconductor Manufacturing

The electronics and semiconductor industry powers the modern world — from smartphones and EVs to aerospace and defense technologies.

In these ultra-sensitive environments, temperature, flow, and pressure accuracy play a crucial role in cleanroom operations, wafer fabrication, and equipment performance.

AAVAD Instrument Pvt. Ltd., a trusted Indian manufacturer of flow meters, thermocouples, RTDs, and transmitters, provides the high-precision instrumentation required to maintain consistency, quality, and global compliance in semiconductor and electronics plants.

💡 1️⃣ The Role of Instrumentation in Electronics Manufacturing

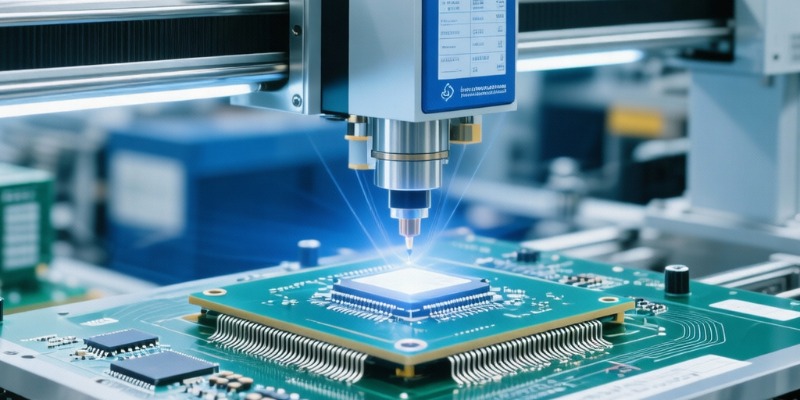

Every microchip, PCB, and electronic component goes through a series of temperature-controlled, chemical, and mechanical processes—including etching, plating, curing, coating, and testing.

Reliable instrumentation ensures:

Stable process conditions

Error-free production

Safe chemical handling

High energy efficiency

🔧 Used In:

Semiconductor wafer fabrication & etching lines

PCB production & automated soldering systems

DI (Deionized) water & chemical dosing systems

🎯 Objective:

To maintain precision and repeatability across all process parameters, ensuring high yield and product reliability.

🌡️ 2️⃣ Temperature Measurement for High-Precision Processes

Temperature is one of the most critical variables in semiconductor manufacturing stages such as CVD, photolithography, annealing, and reflow soldering.

AAVAD’s RTDs and thermocouples deliver ultra-stable readings, protecting delicate components and maintaining tight tolerances.

🔹 AAVAD Temperature Solutions:

RTD Sensors (PT100/PT1000): High accuracy (±0.1°C), ideal for cleanrooms

Thermocouples (K/N Type): Suitable for heating zones & soldering equipment

Surface & Immersion Probes: For reflow ovens and PCB testing setups

✅ Benefits:

Improved chip and PCB quality

Cleanroom-grade SS316L construction

Fast response and excellent long-term stability

💡 Example:

In wafer fabrication, AAVAD’s PT100 RTD sensors maintain uniform temperature in chemical baths, ensuring perfect coating and higher chip yield.

💧 3️⃣ Flow Measurement for Fluids, Gases & Chemicals

Precise flow control is essential for coolants, DI water, specialty gases, and process chemicals used across semiconductor and electronics manufacturing.

AAVAD’s electromagnetic and insertion flow meters offer reliable, maintenance-free performance for continuous monitoring.

🔹 Applications:

DI water circulation loops

Cooling systems & AHUs

Chemical etching and coating lines

Air and nitrogen flow monitoring

🔹 Key Features:

±0.5% accuracy for sensitive chemical processes

No moving parts — zero maintenance

Seamless PLC, SCADA, BMS integration

💡 Example:

In cleanroom water management, AAVAD’s electromagnetic flow meter maintains accurate DI water flow, preventing contamination and costly process interruptions.

🧠 4️⃣ Automation & Industry 4.0 Connectivity

AAVAD instruments support modern, digitally connected factories with technologies that enable remote monitoring, predictive maintenance, and data-driven process control.

🔹 Features:

Modbus RTU / RS485 / 4–20 mA communication

IoT & SCADA compatibility

NABL-traceable calibration

✅ Advantages:

Real-time data logging & traceability

Reduced downtime through predictive alerts

Better regulatory compliance and documentation

💡 Example:

An electronics assembly plant using AAVAD smart transmitters integrated with SCADA systems saw a 15% improvement in cooling water efficiency.

✅ 1. Semiconductor Industry Overview

Intel Semiconductor Manufacturing Info: https://www.intel.com

ISO Standards: https://www.iso.org

SEMI Manufacturing Standards: https://www.semi.org

🏆 AAVAD Advantage Overview

| AAVAD Advantage | Value to Industry |

|---|---|

| ⚡ High Accuracy & Stability | Essential for microelectronics precision |

| 🧾 ISO Certified | Ensures traceable and reliable measurements |

| 💻 Automation Ready | Compatible with SCADA, PLC, IoT systems |

| 🧼 Cleanroom-Ready Design | SS316L, contamination-free components |

| 🇮🇳 Made in India | Trusted for global semiconductor applications |

🏁 Conclusion

In the semiconductor and electronics manufacturing ecosystem, precision is everything.

AAVAD Instruments delivers the accuracy, reliability, and digital compatibility needed to maintain tight process control across wafer fabrication, cleanroom environments, and assembly lines.

With their advanced RTD sensors, thermocouples, flow meters, and transmitters, AAVAD empowers manufacturers to achieve:

Higher production yield

Better energy efficiency

Maximum equipment reliability

Seamless automation

AAVAD Instruments – Precision That Powers Innovation.

Thermocouples: https://www.aavadinstrument.com/product-category/thermocouple-sensor/

RTD Sensors: https://www.aavadinstrument.com/product-category/head-type-rtd-sensor/

Flow Meters: https://www.aavadinstrument.com/product-category/electromagnetic-flowmeter/

Pressure Transmitters: https://www.aavadinstrument.com/product-category/pressure-transmitter/

Shop All: https://www.aavadinstrument.com/shop/