High-Performance Thermocouples for Aluminium Melting Furnaces: A AAVAD Guide

In the aluminium industry, precision and process control are non-negotiable—especially during melting. A few degrees too hot, and you risk excessive oxidation, energy loss, and damage to furnace linings. Too cold, and your casting quality suffers. That’s why having the right thermocouple is essential in aluminium melting furnaces.

🔥 The Role of Thermocouples in Aluminium Furnaces

Aluminium melting involves extreme heat, typically ranging from 700°C to 850°C, and occurs in environments full of molten metal vapors, fluxes, and slag. Thermocouples are the primary temperature sensors that:

Monitor molten metal temperatures

Regulate burner control systems

Trigger alarms for overheating or underheating

Feed data into PLC/SCADA systems for continuous monitoring

Any failure in temperature measurement can cause:

Poor alloy consistency

Dross formation

Increased energy consumption

Reduced furnace life

✅ Choosing the Right Thermocouple Type

Let’s compare popular thermocouples for aluminium melting operations:

| Type | Temp. Range | Accuracy | Cost | Ideal Use |

|---|---|---|---|---|

| K (Nickel-Chromium / Nickel-Alumel) | up to 1260°C | Good | Low | General melting & holding furnaces |

| S (Platinum-Rhodium / Platinum) | up to 1600°C | Excellent | High | Precision melting & billet casting |

| B (Platinum-Rhodium mix) | up to 1700°C | Excellent | Very High | Long-term high-temp processes |

AAVAD offers these in various configurations, including dual-element probes and fast-response tips.

🧱 Sheath Materials That Withstand Molten Aluminium

The harshest enemy of thermocouples in these environments? Corrosion and metal attack from molten aluminium. That’s why sheath selection is as important as the thermocouple type.

| Sheath Type | Properties | Best For |

|---|---|---|

| Ceramic (Alumina / Mullite) | Good thermal resistance, brittle | Low-splash areas |

| Silicon Nitride (Si₃N₄) | High corrosion resistance, thermal shock-proof | Direct immersion |

| Sialon | Non-wetting to aluminium, long life | Continuous melt temperature monitoring |

| Metal-Ceramic (Kanthal Super / Inconel) | Fast response, limited lifespan in Al | Secondary protection or short-term use |

👉 AAVAD’s non-wetting, anti-corrosive thermowells extend thermocouple life by up to 3x in aluminium foundries.

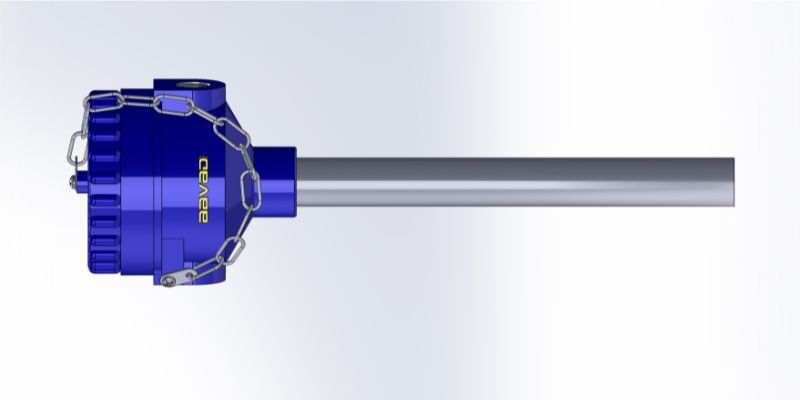

🛠️ Design Options for Custom Applications

At AAVAD, we engineer thermocouples for:

Tilting rotary furnaces

Reverberatory furnaces

Crucible and induction furnaces

Holding furnaces and launders

We offer:

Bayonet and fixed-length probes

Replaceable thermocouple inserts

Integrated signal conditioners

Wireless telemetry for remote monitoring

🧪 Case Study: Foundry in Gujarat Increases Yield by 12%

A major aluminium casting unit in Gujarat was facing frequent thermocouple failures and inconsistent temperature readings. AAVAD supplied Type K thermocouples with Sialon sheaths designed for their crucible furnace. After installation:

Sensor failure dropped by 80%

Aluminium yield increased by 12%

Energy usage reduced by 9%

They now use AAVAD Smart Monitoring Systems to view real-time temperatures on mobile dashboards.

🧼 Maintenance Tips to Maximize Thermocouple Life

Clean the sheath regularly to remove dross and flux buildup.

Avoid rapid temperature changes to prevent thermal shock.

Replace the probe before drift exceeds ±2°C.

Always use high-temperature extension cables with proper cold junction compensation.

🏭 AAVAD – Trusted by Aluminium Industries Across India

With decades of experience, AAVAD thermocouples are used in:

Automotive casting units

Recycling plants

Aluminium extrusion plants

Smelters and alloy manufacturing facilities

We’re also registered on GeM (Government e-Marketplace) and supply to public sector and MSME aluminium industries.

📞 Get a Custom Solution

Not all furnaces are the same. Whether you need a compact sensor for a crucible or a long-lance thermocouple for molten bath insertion, we’ve got you covered.

Contact AAVAD today for expert guidance and custom sensor solutions that last longer and measure better.