Effluent Treatment Plants (ETPs) play a critical role in managing industrial wastewater and ensuring environmental compliance. To maintain operational efficiency and meet regulatory standards, precise measurement and monitoring of flow rates are essential. In this regard, electromagnetic flow meters emerge as indispensable tools offering unparalleled accuracy and reliability in ETPs.

Understanding the Importance of Flow Measurement in ETPs

Effluent Treatment Plants handle diverse wastewater streams with varying compositions and flow rates. Accurate flow measurement is crucial for several reasons:

- Process Optimization: Precise flow measurement enables operators to fine-tune treatment processes, ensuring optimal resource utilization and reducing operational costs.

- Compliance Requirements: Regulatory bodies impose strict limits on effluent discharge. Accurate flow data helps ETPs adhere to these standards, avoiding penalties and legal consequences.

- Resource Planning: Understanding flow patterns facilitates capacity planning and infrastructure upgrades, ensuring the plant can handle current and future wastewater volumes effectively.

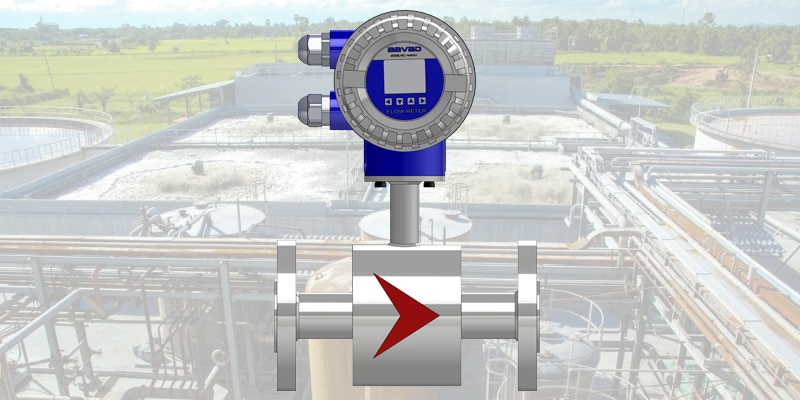

The Role of Electromagnetic Flow Meters

Electromagnetic flow meters, also known as magmeters, are preferred instruments in ETPs for several reasons:

- Accuracy: Unlike mechanical meters, electromagnetic flow meters measure flow based on Faraday’s law of electromagnetic induction. This principle ensures high accuracy, even with challenging fluids or flow conditions.

- Versatility: Magmeters can handle a wide range of flow rates and fluid compositions, making them suitable for diverse applications within ETPs.

- Low Maintenance: With no moving parts to wear out or obstruct flow, electromagnetic flow meters require minimal maintenance, reducing downtime and operational costs.

- Reliability: These meters offer long-term stability and performance, providing consistent and reliable measurements over their operational lifespan.

- Non-intrusive Design: Magmeters feature a non-intrusive design, minimizing pressure drop and the risk of clogging or fouling, especially in applications with solids or debris.

Implementing Electromagnetic Flow Meters in ETPs: Key Considerations

When integrating electromagnetic flow meters into Effluent Treatment Plants, several factors should be considered:

- Selection Criteria: Choose a magmeter model that suits the specific requirements of the application, considering factors such as flow range, pipe size, fluid characteristics, and environmental conditions.

- Installation Location: Install the flow meter in a straight pipe section, away from disturbances like valves, pumps, or elbows, to ensure accurate measurements.

- Calibration and Verification: Regular calibration and verification procedures are essential to maintain accuracy and compliance with regulatory standards.

- Integration with Control Systems: Integrate electromagnetic flow meters with the plant’s control and monitoring systems for real-time data access, alarms, and automated control functionalities.

Conclusion

Electromagnetic flow meters offer unparalleled accuracy, reliability, and versatility, making them indispensable instruments in Effluent Treatment Plants. By providing precise flow measurement data, these meters enable ETP operators to optimize processes, ensure compliance, and enhance overall efficiency in wastewater treatment operations. Investing in high-quality electromagnetic flow meters can significantly contribute to the sustainability and success of Effluent Treatment Plants in meeting their environmental objectives.