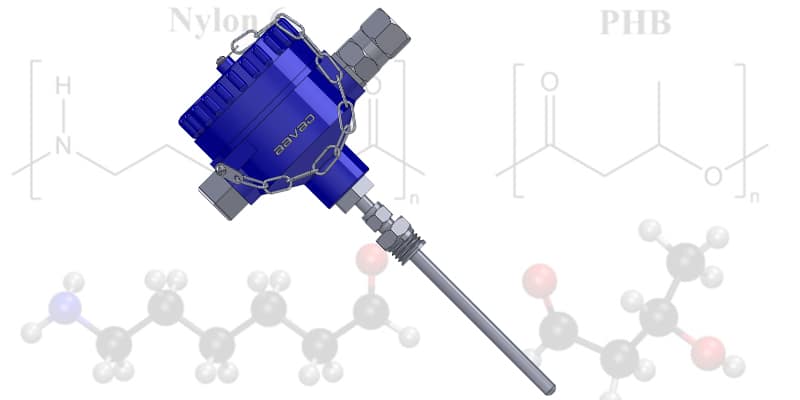

AAVAD Nylon Polymer RTD Sensors

In the dynamic landscape of reactor technology, precision and reliability are paramount. Temperature monitoring is a critical aspect of ensuring optimal reactor performance, and one technology making significant strides in this domain is the Nylon Polymer RTD sensor.

Understanding Nylon Polymer RTD Sensors

RTD sensors play a crucial role in accurately measuring temperature in various industrial applications, including reactors. RTD sensors are known for their high accuracy, stability, and repeatability. Nylon Polymer RTD sensors, in particular, have emerged as a promising solution due to their unique material properties.

Key Advantages of Nylon Polymer RTD Sensors

- Chemical Resistance: Nylon Polymer is resistant to a wide range of chemicals, making RTD sensors suitable for harsh reactor environments where exposure to corrosive substances is common.

- High Mechanical Strength: The inherent strength of Nylon Polymer ensures durability, enabling the sensors to withstand mechanical stress and vibrations within the reactor.

- Wide Temperature Range: Nylon Polymer RTD sensors can operate efficiently across a broad temperature spectrum, making them adaptable to the diverse conditions encountered in reactor systems.

Applications in Reactor Environments

- Optimizing Reaction Conditions: Nylon Polymer RTD sensors enable precise temperature control, ensuring optimal conditions for chemical reactions within the reactor.

- Enhanced Safety: Accurate temperature monitoring is essential for ensuring the safety of reactor operations. Nylon Polymer RTD sensors contribute to early detection of abnormal temperature variations, helping prevent potential hazards.

- Process Efficiency: The high accuracy of Nylon Polymer RTD sensors contributes to increased process efficiency by maintaining temperature within specified ranges, ultimately leading to better yield and reduced energy consumption.

Integrating Nylon Polymer RTD Sensors

Integrating Nylon Polymer RTD sensors into reactor systems is a straightforward process. Their compatibility with standard instrumentation and control systems makes them a practical choice for both new installations and retrofitting existing reactors.

Conclusion

In the realm of reactor technology, where precision and reliability are non-negotiable, Nylon Polymer RTD sensors stand out as a valuable tool for temperature monitoring. Their chemical resistance, mechanical strength, and wide temperature range make them well-suited for the demanding conditions within reactors. As industries continue to advance, embracing innovative solutions like Nylon Polymer RTD sensors is pivotal for achieving optimal performance and safety.