A capillary is generally built up from a tube, an armor, and optionally a protective sleeve.

Table of contents

- Principle

- Importance of Capillary Tubing

- Tube Size

- Capillary Tube Material

- Precautions

- Process Temperature Effect

- Ambient Temperature Effect

- Mounting Effect

- Advantages

- Disadvantages

- Applications

Principle

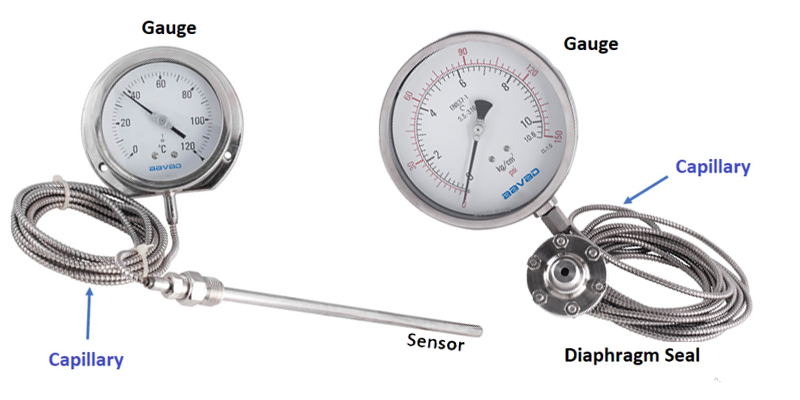

The capillary tube is of small internal diameter, an appropriate method for separating a pressure instrument such as a gauge or transmitter from the process tapping/connection.

Capillary tubing is used to separate the direct connection between the measuring instrument and the process tapping point.

We can install the instrument as per our convenience and easy access for the maintenance. The capillary tubing is filled with some liquid inside it, usually it is glycerine but can be changed as per application need.

With help of this, the readings can be taken at a more convenient and accessible location to meet the demand for remote measurement/reading.

Capillary tubes also serves as the purpose of a cooling element as the distance between the process tapping and the instrument will be more than the direct type installation. Also, there will be no direct contact between the instrument sensor and the process.

Importance of Capillary Tubing

A capillary tube is commonly used to connect the diaphragm seal remote with the pressure instrument.

It allows separation between the measuring instrument such as pressure gauge or transmitter with the process connection.

Using a capillary tube on a mechanical gauge normally requires the use of a gauge supporting arrangement and gauge adaptor or some other form of surface mount.

In a temperature measurement, the pneumatic temperature transmitter is connected with a sensor.

The sensor is a bulb filled with either mercury, gas, or vapor.

Through the capillary tube, expanded bulb fill makes the movement of the bellows or a C – Type bourdon tube as per the corresponding temperature of the process medium.

The transmitter is located at an accessible place.

Tube Size

1/16 inch to 1/8 inch capillary tubes are used in instrumentation applications.

Capillaries with suitable diameters are used for optimal performance.

Capillary Tube Material

- Stainless steel,

- Copper,

- Inconel,

- Hastelloy.

Precautions

Precautions when using a capillary tube:

- Process temperature effect.

- Ambient temperature effect.

- Mounting effect.

Process Temperature Effect

Process temperature effect on the diaphragm seal and of the fill fluid in the capillary through heat transfer.

The capillary tube has an excellent function for cooling down of process temperature changes.

But, the warming through of the process media temperature that causes the capillary tube to fill liquid to either expand or contract, the possibility of changing the volume of the fluid.

This is possible in the case of the short length of the capillary, this generates an error in the pressure reading as a function of the change of total volume of the tubing, pressure instrument, and diaphragm seal.

Ambient Temperature Effect

It includes seal temperature effect and ambient temperature effect.

Exposure of an electronic pressure transmitter to excessively high ambient or process temperature can impair the instrument operation, affect its performance or even lead to a partial or total failure of the instrument.

To prevent exposure to excessively high ambient temperatures.

Consider installing the instrument in a safe area from major heat sources.

In extremities, cool down the instrument vicinity using compressed air or any equivalent mean.

The seal temperature effect relates to the pressure produced on the diaphragm when the temperature changes. The pressure is corresponding to an expansion or contraction of the fill fluid in the capillary.

Mounting Effect

A level difference between the installed pressure instrument and the diaphragm seal creates a pressure indication error.

But, by the method of a known level difference can be compensated for during the calibration of the diaphragm seal assembly.

On differential pressure (DP) applications, the sealing effect is usually compensated by having the same length of capillaries for both LP and HP ports of the instrument.

Advantages

Protecting the instrument from high or low process temperature effects.

Personnel safety due to proper accessibility.

Disadvantages

Longer capillary lengths affect the accuracy as subjected to ambient temperature effects.

Capillary length to be as short as possible to avoid delay response time.

Applications

- Distant reading.

- Capillary is to be used in combination with gauges, diaphragm seals, transmitters, switches.

- Chromatography.